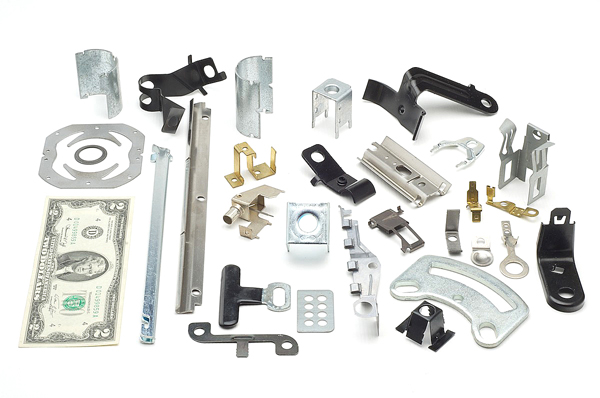

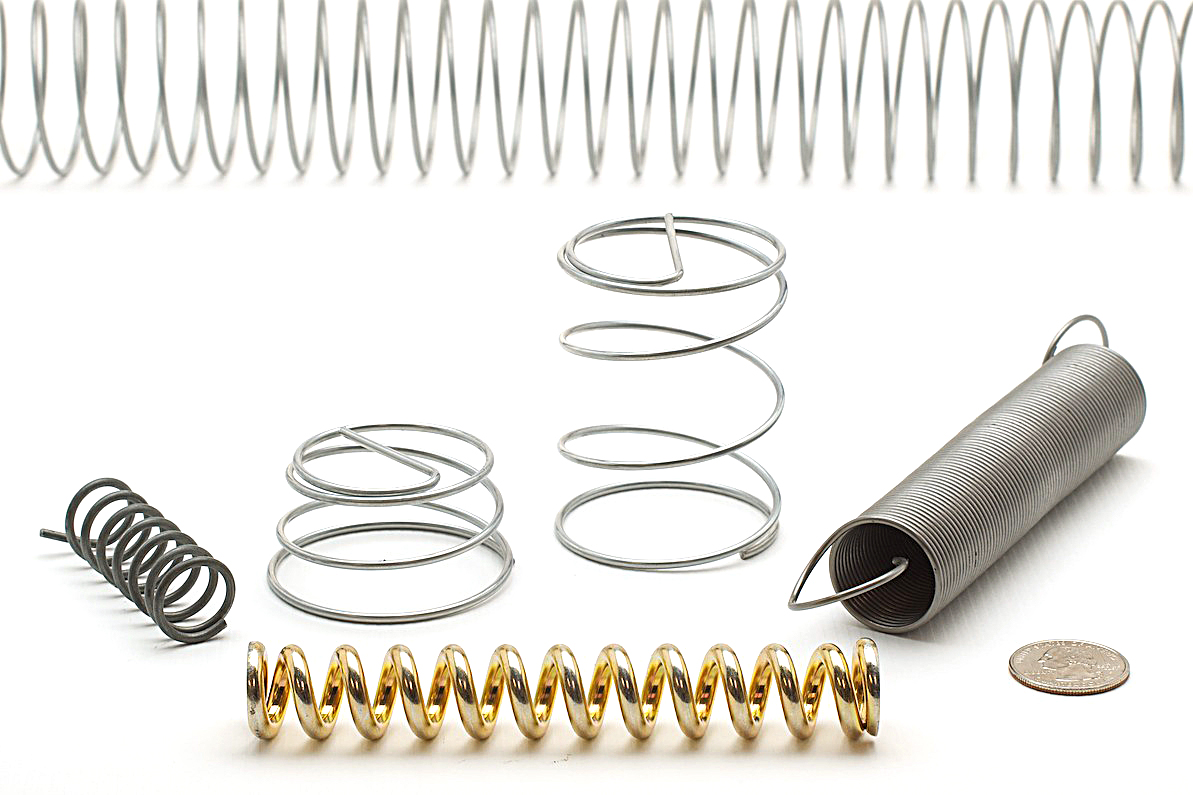

Ampex excels at high volume production. We have comprehensive metal stamping capabilities up to 600 ton, extensive 4-slide and mutli-slide options along with high precision CNC wire forming and CNC spring coiling.

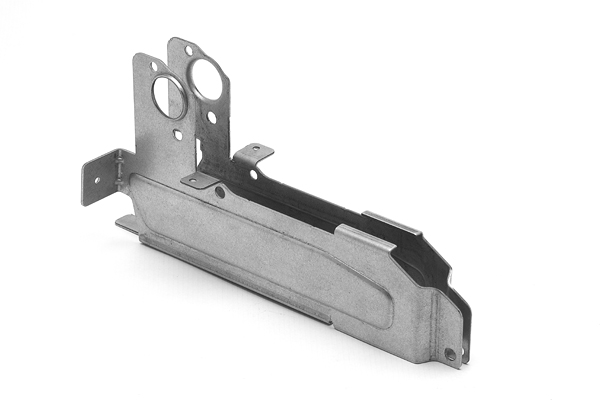

Metal Stamping

At Ampex, we combine our vast metal forming experience with a drive for enhanced customer satisfaction through continuous improvement and innovation. Not a single decision is made without consideration to "How will this effect our Customer?"

Our stamping capabilities range from 22 to 600 ton allowing us to meet a wide range of Customer needs.

It is our choice to run primarily Minster presses because of the outstanding build quality and high reliability of this equipment. We have also standardized on Link motion controllers, Link die protection sensors, VAMCO feed units and Cooper Weymouth uncoilers.

This combination of world class equipment provides us with a very high level of predictability and uptime. It also allows our Operators to move between machines with complete confidence and competence.

Most importantly, every press is equipped with state of the art safety light curtains. These are presence detection devices designed to safeguard our Staff while working in and around our equipment.

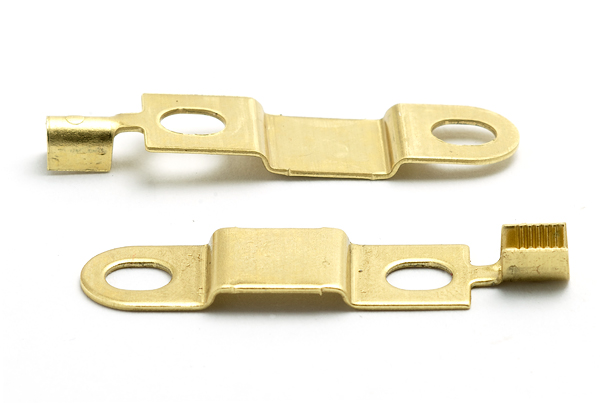

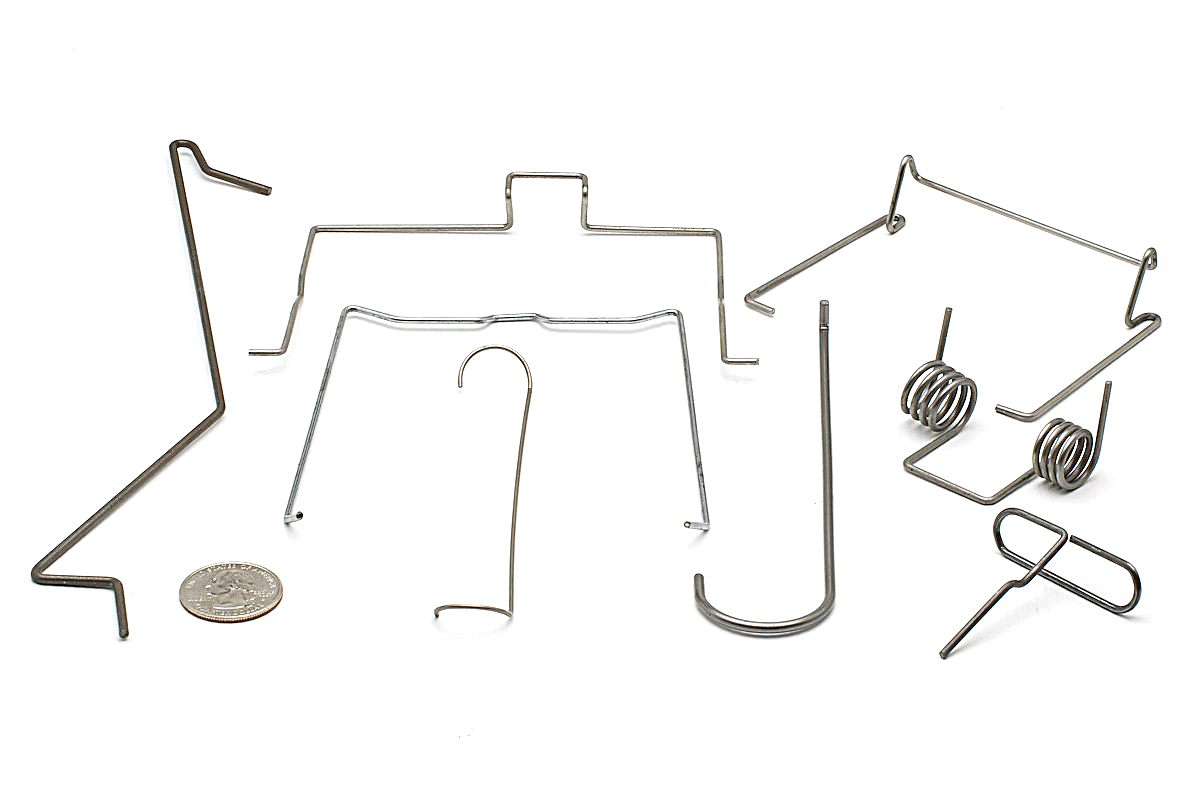

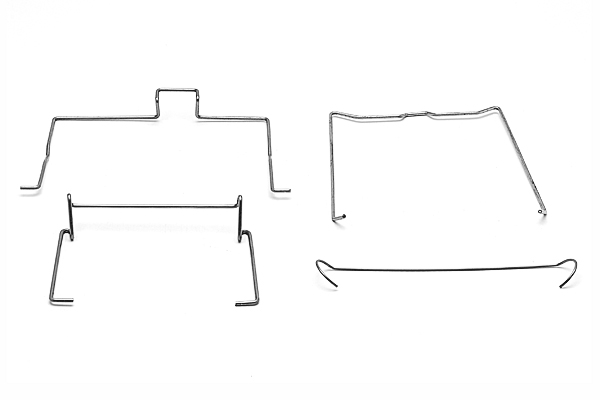

4-Slide & Multi-Slide

Ampex continues to offer and will remain, one of very few 4-Slide and Multi-Slide experts remaining in this industry. Our commitment to this art form is immense and we have ensured capacity for this type of manufacturing through strategic acquisition, in-house innovation and ongoing customization.

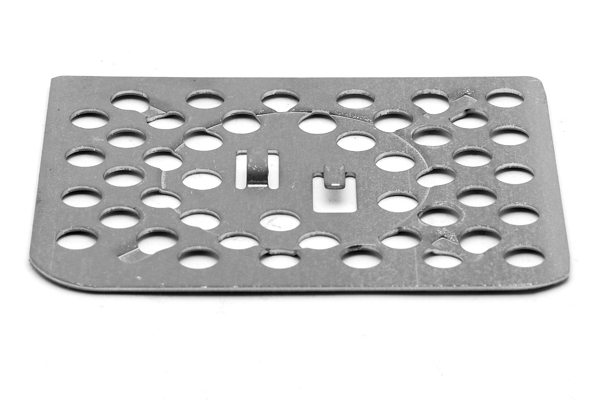

This style of metal forming is radically different from most other metal stamped processes. Primarily, this metal forming technique is ideally suited for the high-volume manufacture of formed components from flat coil or wire stock.

A well designed set of tools will yield high precision components with a minimum of scrapped material, driving down the cost per unit made. This is a level of expertise that is hard to find, fortunately at Ampex, we know how to achieve these results.

As with our all of our production equipment, we employ standardized controls along with die protection to ensure safety while maximizing reliability and productivity.